Understanding RFID

What is RFID?

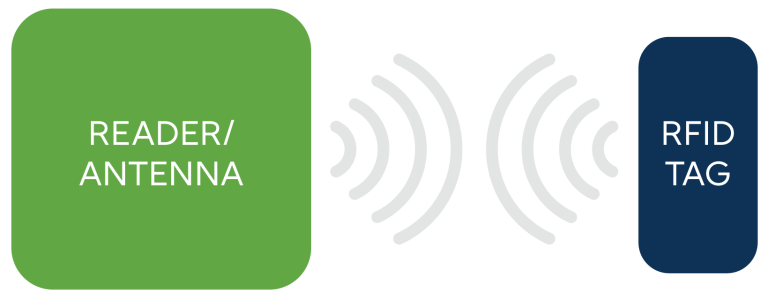

Radio-Frequency Identification (RFID) is the use of radio waves to read and capture information stored on a tag attached to an object. The tag can be read from several meters away and does not need to be within direct line-of-sight of the reader to be tracked.

Benefits of RFID

No line of sight required

Uniquely identifies individual items

Read multiple tagged items simultaneously

Automates data collection

Industries

Companies in a wide variety of industries are seeking solutions to help them improve the efficiency of their textile management processes. Whether its garments, flat goods, blankets, pillowcases, privacy curtains, sheets, towels, microfiber mops, aprons, coveralls, hospital gowns, scrubs or uniforms, Positek RFID helps manage textile needs more efficiently, improving customer service and boosting your bottom line.

What We Do

Positek RFID creates and installs custom-designed textile and laundry management solutions that enable companies to reduce labor costs, improve productivity, cut merchandise costs, eliminate shortages, and accurately track, sort and inventory goods. Each of these benefits adds value to the business operations increasing profitability.